Process engineering for water treatment

The topic of water and the associated process engineering for water treatment and improvement of water quality encompasses our entire lives, on which the state of our health, environment and prosperity depends. EKK Anlagentechnik has set itself the task of finding the most effective ways of implementing systems for waste water and the production of pure water. The (waste) water quality depends on many individual chemical, physical and biological parameters that require customised solutions by experts.

EKK range of services – Process engineering for water treatment

Depending on the existing framework conditions, it is our aim to offer you ecologically and economically sensible and compact system solutions from consultation through to commissioning. Contact us if you need a solution for your water treatment system. With EKK Anlagentechnik, you have a flexible and competent partner with comprehensive expertise, a high knowledge of production and a sense of responsibility at your side.

Our range of services includes:

- Consultancy/planning

- Design

- Engineering

- Systems engineering

- Adjustments on site

- Prefabrication of system stations

- Pipeline construction

- Tank construction

- Modernisation of old systems

- Installation

- Systems service and maintenance

- Training

Raw water treatment

The raw water must be specially treated for the individual treatment processes. The following parameters often play a role here:

- Degree of hardness

- Concentration of foreign substances

- Debris particles

- Oxidising substances

Precipitation and flocculation of unwanted components

A precipitation or flocculation station with subsequent filtration is often installed upstream to remove unwanted components in the (waste) water. These are primarily used to bring about a chemical reaction or agglomeration of the flocculants with the components to be dissolved out of the water and to allow these to sediment in a container provided for this purpose. Changing the pH value with the help of chemicals can also favour the precipitation of certain heavy metals, for example.

Disinfection of process water

The continuous disinfection of process water plays a very important role, particularly in the swimming pool sector. The contaminated water can be continuously treated with the help of a filter unit to remove coarse particles and the addition of a chlorine dioxide solution or a concentrated salt solution, as well as optional additional UV irradiation, so that nothing stands in the way of swimming fun.

Membrane process

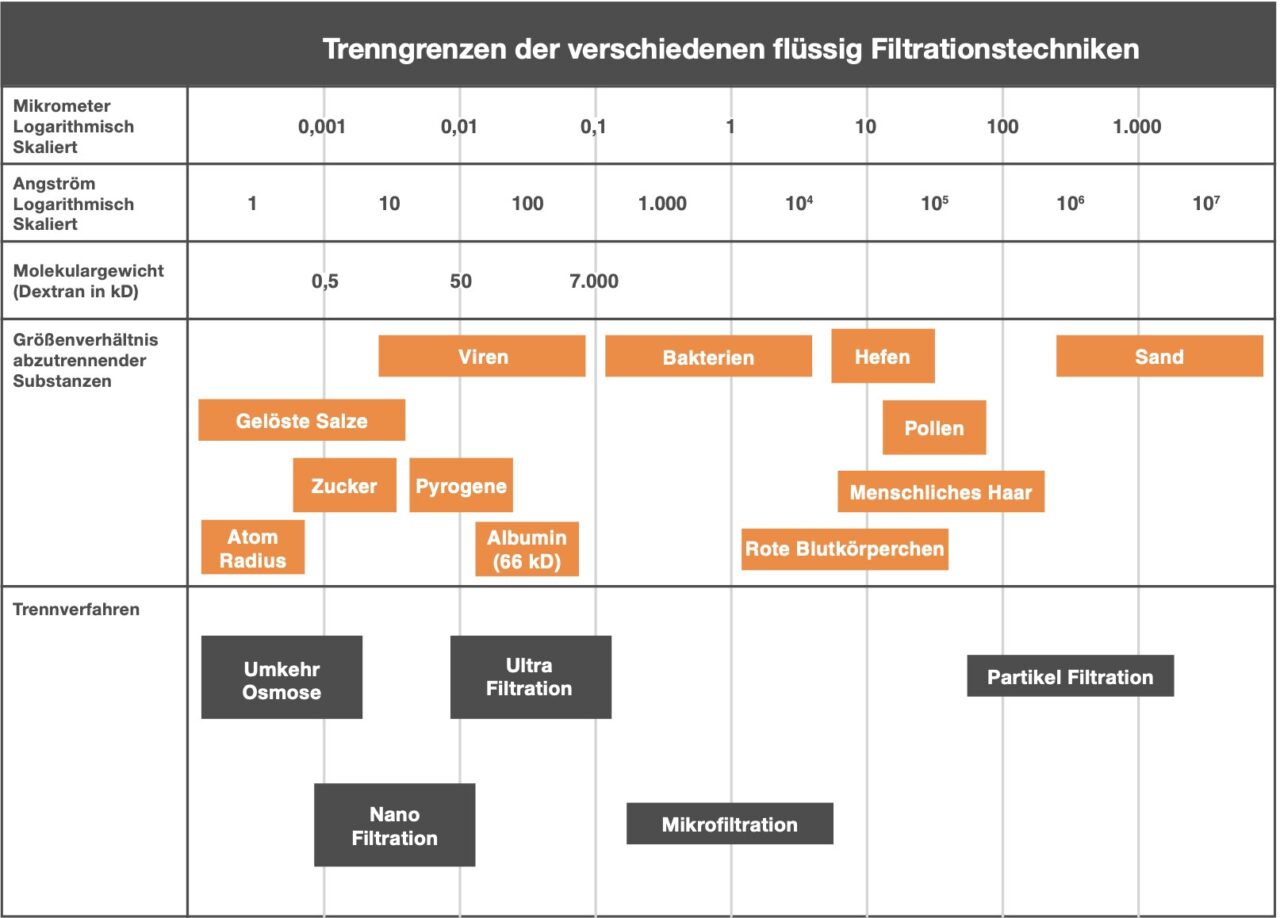

In the membrane process, the raw (waste) water is pressed at high pressure against a fine-pored plastic membrane, which acts like a very fine filter and only allows small water molecules to pass through. The semi-permeable membrane is usually constructed in wound modules that are located in a pressure pipe. The product that passes through the membrane is called permeate. The somewhat larger molecules, such as the ion complexes, oils, colloidal particles or trace substances dissolved in the raw water, cannot pass through the membrane and concentrate in the residue on the reactant side. The decisive parameters for dimensioning these energy-intensive components are the throughput pressure, the permeate volume and the return flow ratio. The reverse osmosis system can produce almost pure water with a very low conductivity. The individual processes are listed below with regard to their pore size and the associated separable substances, as well as the required differential pressures:

| Procedure | Microfiltration | Ultrafiltration | Nanofiltration | Reverse osmosis |

| Pore size [10-3 mm] | > 0.1 | > 0.01 | > 0.001 | > 0.0001 |

| Pressure differential range | 0.1 – 2 bar | 0.1 – 5 bar | 3 – 20 bar | 10 – 100 bar |