CNC contract manufacturing

As an established provider of CNC contract manufacturing in Germany, EKK Anlagentechnik is always at the cutting edge of technology and is therefore a close partner of renowned customers throughout the German-speaking world. We manufacture customised sample components, take over series production and support you in the development of your product. Our trained design engineers offer you expertise and many years of experience in the planning, construction and design of a wide range of components. We design and produce your workpieces based on simple sample parts or drawings and accompany the entire process through to the finished product.

Raw materials and materials that are always in stock guarantee our customers the shortest delivery times and on-time production. We also offer you a broad repertoire of other processing steps such as the bonding and welding of plastics as well as the pre-assembly of various components into finished assemblies in order to relieve and support your production in the best possible way.

Benefit from direct contact partners, close cooperation and open communication. EKK Anlagentechnik is your trustworthy and reliable outsourcing partner for CNC contract manufacturing in Germany. Contact us now and we will take over the design, production and further processing of your CNC precision components. Fair conditions and short delivery times guaranteed!

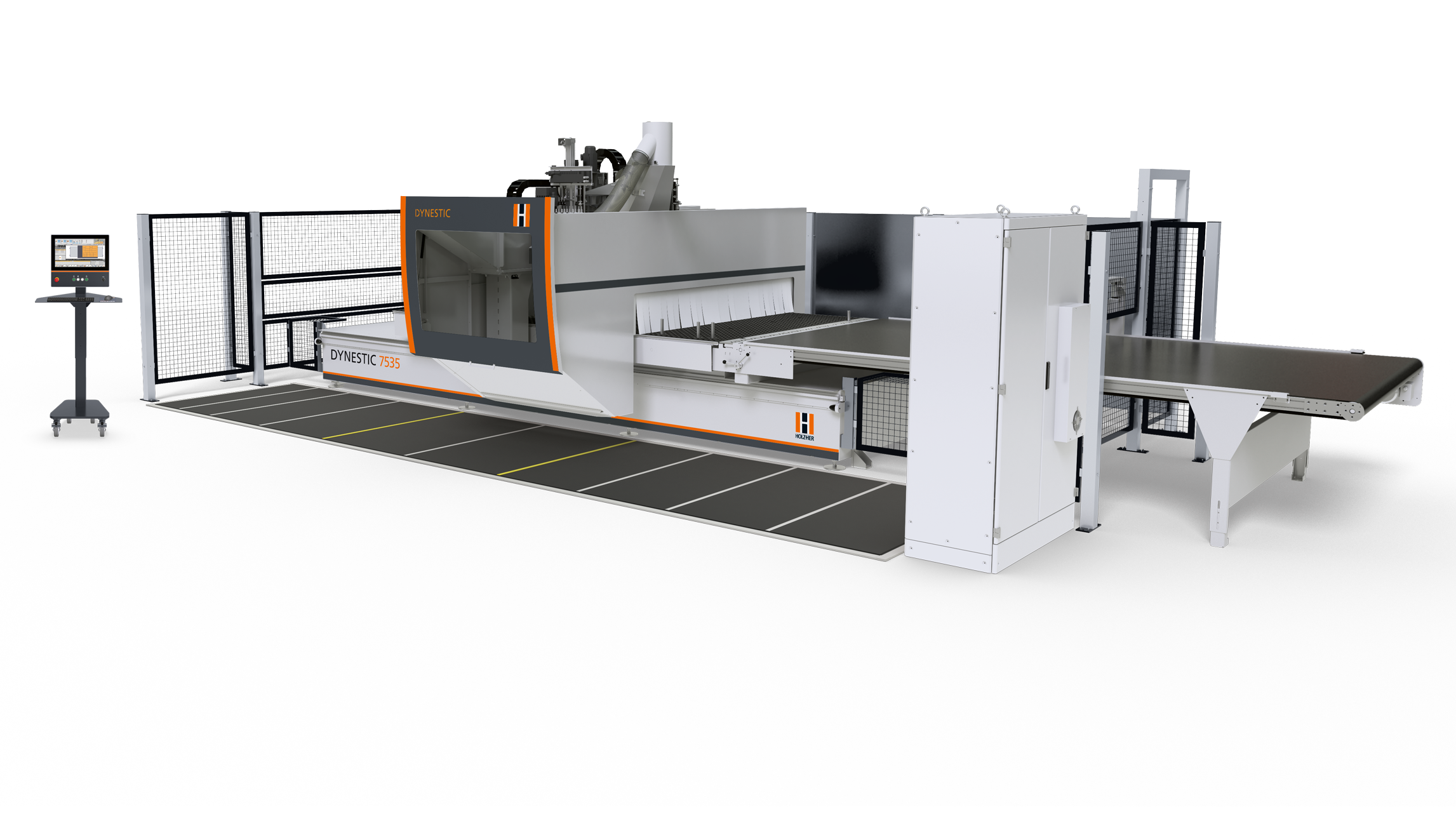

CNC contract manufacturing: Introduction to the 5-axis milling machine

CNC milling – quality with computer-aided precision

CNC milling work is a high-precision process based on computerised numerical control. It is suitable for the production of both small and large quantities.

EKK uses 3- and 5-axis milling machines to machine a wide variety of components with an accuracy of +/- 0.05 mm. Our main focus here is on

- the integration and further development of the CAD/CAM process chain

- the optimisation of raw material utilisation with modern nesting software

- the minimisation of manual reworking of components

CAD/CAM programming – Flexible CNC contract manufacturing

CAD/CAM programming is the creation of programs for computer-aided design (CAD) and computer-aided manufacturing (CAM) to control machine tools.

Innovative 3D programming systems and simulation software enable the realisation of even highly complex workpieces. The CAD/CAM software is used worldwide to control CNC machines.

Your CAD data is imported directly into our CAM system. If no drawings are available, we will create a 3D model according to your specifications or on the basis of a sample. This forms the basis for the milling strategy in the CAD/CAM system.

CNC cutting – with an oscillating cutter head

The high-frequency oscillating tangential cutting head of our CNC cutting machine allows us to precisely produce complex contours and designs, making us particularly efficient in CNC contract manufacturing. In particular, materials such as EPDM seals, corrugated cardboard, templates made of thick films and other materials that are not suitable for machining processes can be processed effortlessly using our modern CNC cutting machine. We offer maximum flexibility and shorter delivery times. That’s because we manufacture at our sites in Friedberg and Ziemetshausen, where we have a wide range of different raw materials at our disposal.

We produce individual items and series for our customers and partners with consistently high quality in the field of CNC contract manufacturing. Even complicated designs with tight tolerances of just a few hundredths of a millimetre can be produced quickly and cutting with optimised waste on a processing area of 4 x 2 metres. Thanks to the latest version of our nesting software, we are able to manufacture in a particularly resource-efficient way thanks to free-form nesting. We pay attention to the sustainable use of raw materials and rely on advanced manufacturing processes in CNC contract manufacturing.

Technical data for CNC contract manufacturing:

- Processing dimensions: X- 4600 | Y- 2200 | Z-axis: 250 mm max.

- Tolerances: +/- 0.05 mm

- Supported 2D file formats: DXF, DWG, IDW, DGN

- Supported 3D file formats: STEP, IPT, CATPart

- Batch sizes: 1 to …

materials for machining:

- Thermoplastics (PE, PP, PA, POM, PVC, etc.)

- Non-ferrous metals

- Insulating materials

- Steel

- Stainless steel

- Brass

- Tool steel

Materials when processing with the oscillating blade:

- Sealing materials (EPDM, Viton, Abil)

- Elastomers

- Corrugated cardboard

- Films

- Foams

Are you looking for a partner in the field of CNC contract manufacturing? Contact us so that we can clarify your requirements and support you with our technical expertise.

We are your partner for the professional implementation of your wishes, whether for prototypes, individual parts or series production.

Advantages of CNC contract manufacturing from EKK Anlagentechnik at a glance:

- Many years of experience & expertise

- Made in Germany (production in Friedberg & Ziemetshausen)

- Qualified specialist staff

- Flat hierarchies

- Motivated employees

- Direct contact persons

- In-house design (it is possible to create a drawing based on a sample component and manufacture it based on this)

- Shortened delivery times (large number of raw materials in stock)

- Even more processing steps possible in-house (e.g., plastic welding)

Frequently asked questions about CNC contract manufacturing:

Why does it make sense to outsource CNC production?

There can be many reasons for outsourcing CNC production. The following reasons speak in favour of CNC contract manufacturing:

- On-schedule production in the event of production bottlenecks

- Fluctuating capacity requirements (machine utilisation)

- The production of special components and small series

- Large-format components

- Lack of access to raw materials or poor purchasing conditions

- No expertise with the corresponding material

How is the quality of the milled parts ensured in CNC contract manufacturing?

The quality of our products and, above all, the satisfaction of our customers are both very important to us. All our CNC contract manufacturing products are delivered to our customers with outstanding functionality, reliability and quality.

We are a certified company according to the ISO 9001 standard for quality management systems. Regular audits and recertifications ensure compliance with our quality standards.

Which plastic is suitable for my requirements?

Thanks to our many years of experience in the field of plastics processing, we can support you in the selection of materials. Depending on the area of application, the plastic must have individual properties, such as UV, oil and solvent resistance, buoyancy or weather resistance. Thanks to our technical expertise, we can provide you with comprehensive and competent advice when choosing the optimum material.

How are the CNC parts delivered?

Depending on the order volume, the finished components are packed in appropriate protective packaging and delivered by parcel or freight company. Basically, we offer you fast order processing and can organise scheduled or express delivery on request.